In my work I try to cover the full gamut of "technology", from working with villages in developing countries to advising multi-nationals on how to lay out their far flung factories for optimal efficiency. If you have a need for "lean six sigma" and things like statistical process control, plant layout (large or small), factory physics, metallurgy/materials science, new business development and product introduction, cutting edge R&D, technical documentation of the best kind, and similar - now you know where to find me. I have a technical bent, and I try to exercise it in both my vocation and avocations - finding solutions that provide clean water, smoke free kitchens, stronger alloys, cheaper consumer goods, and better medical devices is what I do, but change engineering better describes what is important to me. It often turns out that the technology part is easy, but getting it adopted in a way so that its potential is realized is the challenge. I tend to spend a lot of time sitting and absorbing the present situation, while pondering how to get to the one envisioned - language and cultural barriers are common on my projects, so rushing things rarely helps. Solutions tend to involve more people than was originally expected, and more kinds of skills. I thrive on excellent reporting, so that experiences are not lost.

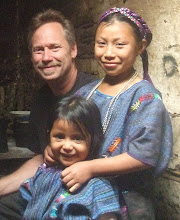

In my work I try to cover the full gamut of "technology", from working with villages in developing countries to advising multi-nationals on how to lay out their far flung factories for optimal efficiency. If you have a need for "lean six sigma" and things like statistical process control, plant layout (large or small), factory physics, metallurgy/materials science, new business development and product introduction, cutting edge R&D, technical documentation of the best kind, and similar - now you know where to find me. I have a technical bent, and I try to exercise it in both my vocation and avocations - finding solutions that provide clean water, smoke free kitchens, stronger alloys, cheaper consumer goods, and better medical devices is what I do, but change engineering better describes what is important to me. It often turns out that the technology part is easy, but getting it adopted in a way so that its potential is realized is the challenge. I tend to spend a lot of time sitting and absorbing the present situation, while pondering how to get to the one envisioned - language and cultural barriers are common on my projects, so rushing things rarely helps. Solutions tend to involve more people than was originally expected, and more kinds of skills. I thrive on excellent reporting, so that experiences are not lost.I live in Geneva, Switzerland now, arriving here from the San Francisco area where I worked in medical device development and learned to help the world through Engineers Without Borders and Catapult Design. Through them I have been fortunate enough to work with communities all over the world, advising in such areas as biomass powered electricity microgrids (India), ruggedized wheelchair manufacturing (Indonesia and Vietnam), improved cooking stoves (Peru, Guatemala, Darfur, and more), sustainable energy for hospitals (Rwanda), better agricultural practices (Africa), improved latrines (Cambodia), and financing mechanisms for renewable energy projects (Costa Rica). I particularly specialize in working with organizations to scale up their new products, so that they can deliver the maximum impact by delivering the best quality at the lowest cost.

Before that, I worked in China for 2 years manufacturing rare earth permanent magnets for Magnequench International - a fascinating experience, that gave me invaluable experiences in every aspect of manufacturing, from supply chain development to quality assurance. I came to love hands on factory physics via an unusual path, having started my career at the U.S. Department of Energy's Idaho National Laboratory, where I conducted both basic and applied research for 10 years. Along the way we invented new ways of making advanced materials by rapid solidification, and I jumped at the chance to migrate to the private sector and commercialize these.

Before that, I worked in China for 2 years manufacturing rare earth permanent magnets for Magnequench International - a fascinating experience, that gave me invaluable experiences in every aspect of manufacturing, from supply chain development to quality assurance. I came to love hands on factory physics via an unusual path, having started my career at the U.S. Department of Energy's Idaho National Laboratory, where I conducted both basic and applied research for 10 years. Along the way we invented new ways of making advanced materials by rapid solidification, and I jumped at the chance to migrate to the private sector and commercialize these. You can request more information by emailing me at csellers42 (at) yahoo.com.

No comments:

Post a Comment